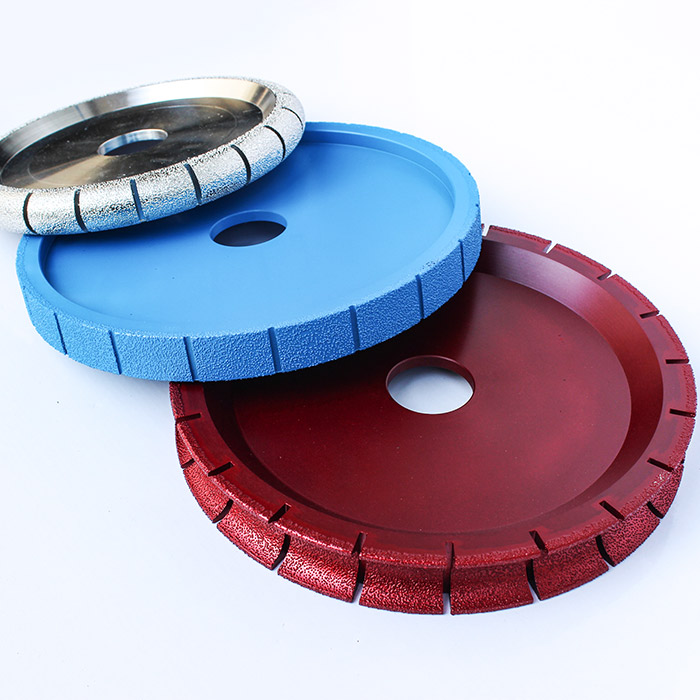

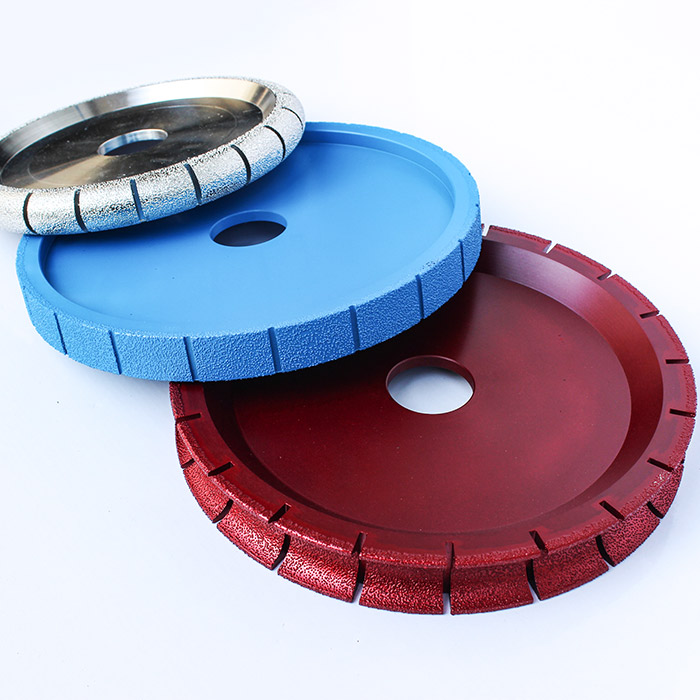

These vacuum brazed diamond tools are used for grinding in natural factories mostly. The most important thing is cost. Then our vacuum brazed diamond grinding disc/grinding wheel has such advantages. First, the work efficiency of workers is increased by more than 40%, which saves labor costs. Secondly, the long lifespan saves the workers the need to frequently replace the grinding wheel/grinding wheel, which saves costs. In addition, our vacuum brazed diamond grinding wheels can guarantee more than 80 times the service life of traditional resin cast iron grinding wheels. Our vacuum brazed diamond grinding discs/grinding wheels are also very cost-effective. Finally, our vacuum brazed diamond grinding discs/grinding wheels will not generate a lot of waste and dust, thus saving cleaning and transportation costs. High safety also avoids economic losses caused by operating accidents or health factors.

The vacuum brazed diamond grinding disc/grinding wheel will not break during use. Different from the traditional resin cast iron grinding wheel, there is a risk of cracking and safety accidents if it is used improperly. This is because we use the preferred special steel, unique structural design, and the base as a whole, which fundamentally eliminates the possibility of breakage.

This means that during the grinding process, the vacuum brazed diamond grinding wheel will not lose sand and wear. No dust is generated, which is beneficial to the health of workers. In addition, the traditional resin cast iron grinding wheel is cured with resin. When the temperature is high, the resin will melt, not only will sand fall, but the gas emitted by the resin is toxic and harmful to the human body.

This is because we have designed a unique vibration-absorbing structure and adopted special elastic damping materials, which greatly reduces the grinding vibration of the grinding disc/grinding wheel and improves the comfort of the product.

There are two reasons for traditional grinding to produce sparks: one is the polished metal, and the other is the sand droplets of the resin cast iron grinding wheel itself. Due to the poor chipping effect of the traditional resin cast iron grinding wheel, the grinding surface temperature is very high, so it is easy to produce a lot of sparks. Moreover, the abrasive grains on the surface of the vacuum brazed diamond grinding disc are diamond, which is welded on the base, with high exposure and good heat dissipation effect. Due to the low temperature, it is not easy to produce sparks. On the other hand, our vacuum brazed diamond grinding wheels will not lose sand, and the base will not wear, so the sparks are smaller.

The key to the long life of vacuum brazed diamond grinding discs is our technology and equipment. The new generation of welding technology guarantees the high-strength welding of diamond. High-performance vacuum brazing equipment ensures the excellent performance of diamond. This can ensure that the diamond particles wear little during use and will not fall off. The service life is greatly extended. Therefore, even single-layer diamond tools can reach hundreds of times that of ordinary cast iron grinding discs/grinding wheels.

The vacuum brazed diamond disc/grinding wheel uses molten diamond technology. Its surface is high-temperature welded diamond, not corundum abrasive for grinding wheels. Diamond is the hardest substance, with high hardness and sharpness, and a high removal rate of materials. In addition, a new generation of diamond tool manufacturing technology-fusion technology can ensure that the diamond exposure is very high (up to 50%) and can still be welded firmly.

The vacuum brazed diamond grinding disc/grinding wheel will not break during use. Different from the traditional resin cast iron grinding wheel, there is a risk of cracking and safety accidents if it is used improperly. This is because we use the preferred special steel, unique structural design, and the base as a whole, which fundamentally eliminates the possibility of breakage.

This means that during the grinding process, the vacuum brazed diamond grinding wheel will not lose sand and wear. No dust is generated, which is beneficial to the health of workers. In addition, the traditional resin cast iron grinding wheel is cured with resin. When the temperature is high, the resin will melt, not only will sand fall, but the gas emitted by the resin is toxic and harmful to the human body.

This is because we have designed a unique vibration-absorbing structure and adopted special elastic damping materials, which greatly reduces the grinding vibration of the grinding disc/grinding wheel and improves the comfort of the product.

There are two reasons for traditional grinding to produce sparks: one is the polished metal, and the other is the sand droplets of the resin cast iron grinding wheel itself. Due to the poor chipping effect of the traditional resin cast iron grinding wheel, the grinding surface temperature is very high, so it is easy to produce a lot of sparks. Moreover, the abrasive grains on the surface of the vacuum brazed diamond grinding disc are diamond, which is welded on the base, with high exposure and good heat dissipation effect. Due to the low temperature, it is not easy to produce sparks. On the other hand, our vacuum brazed diamond grinding wheels will not lose sand, and the base will not wear, so the sparks are smaller.

The key to the long life of vacuum brazed diamond grinding discs is our technology and equipment. The new generation of welding technology guarantees the high-strength welding of diamond. High-performance vacuum brazing equipment ensures the excellent performance of diamond. This can ensure that the diamond particles wear little during use and will not fall off. The service life is greatly extended. Therefore, even single-layer diamond tools can reach hundreds of times that of ordinary cast iron grinding discs/grinding wheels.

The vacuum brazed diamond disc/grinding wheel uses molten diamond technology. Its surface is high-temperature welded diamond, not corundum abrasive for grinding wheels. Diamond is the hardest substance, with high hardness and sharpness, and a high removal rate of materials. In addition, a new generation of diamond tool manufacturing technology-fusion technology can ensure that the diamond exposure is very high (up to 50%) and can still be welded firmly.

Previous:How to Adjust The Balance of Diamond Grinding Wheel Next:Concrete floor grinding and polishing steps

Thank you for your interest in the above content, please leave us inquiry, you can expect a response within 24 hours.

Required fields are marked *

|

|

|

|