In 2004, I got involved with diamond saw blades in my family Retail Tools Store. We bought a new diamond saw blade by laser welded technique to allow dry cutting without water. Before that, most of granite saw blade and concrete saw blades were silver welded (brazed) and abrasive saw blades ruled the whole diamond tools market. As we know, the price of one 350mm diamond saw blade for granite was $150 more and the applications were very limited. We tried to sell this expensive diamond saw blade but the users came back with various problems. Diamond saw blades were remade again then to be used only in some special applications. If cutting objects had a little differences in aggregate or hardness, we needed to use another diamond saw blade with different bond to test again. Usually the operator did not know the actual character of the application, and the store sales resulted in failure and we had to close up. When I was just a teenager, I decided to find a way to have these blades work properly and well for our us and decided to learn everything I could about diamond saw blades for cutting all kinds of construction materials.

No doubt, the diamond tools supplier has changed greatly from then on. The bond formula used today is much more tolerate, and the costs for cutting have dropped as much as 80% over the past 15 years. The lower cost has urged the market to a much greater team of diamond saw blade users and correspondingly volume has increased greatly. If you’re a new operate of diamond saw blades (diamond cutting blade), please think yourself have good luck that you didn’t to through the growing pains of the diamond tools industry. The charges are as lower as you will find totally, but there is still a very wide scope of price and quality grades available for you to select from. The most big problem you will encounter now is how to determine what diamond blade makes sense for you to use. However, there is no written standard on leveling diamond saw blades for cutting stone. You will find diamond saw blades labeled as “premium quality” that are actually not. In fact, most of the marketers call their whole production line premium, regardless of real quality and truth. We offer true diamond saw blade grading, based on its performance when cutting granite, marble and concrete. We offer precise 6 levels of quality based on the product type. Our company rule is that for every 15% more you spend on the diamond blade, you would see a minimum of a 25% increase in cutting performance and the output. Happily most of our diamond blades exceed that rating.

So at present you have knew that many of the quality ratings listed are meaningless, what should you pay attention to in a diamond saw blade? What’s correct for a user probably won’t be the same for others, so let us break this down by detailed requirements. We’ll take 14” concrete saw blade as the model since that is the biggest volume product which are sold around the world.

Price – Many users always look at the original cost of a diamond saw blade as the elemental factor when doing purchase. If you are planning to make a small amount of cuts and won’t have any further need for the diamond saw blade, it is the correct choice. You want the possible lowest costs connected with the job. What you don’t want is something too cheap to bring danger. In reality, a heavy user shouldn’t select price as his want. A higher priced diamond saw blade for concrete or stone will always yield much lower cost per foot than an economic diamond saw blade. For Example:

Cutting 3000psi cured concrete with medium aggregate and #3 steel bar, these are estimated inch feet for ChinShine brand concrete saw blades by quality (+/- 30% depending on operator and saw):

• 14BSM0.4 – 1000 inch feet Average street price $40 Cost per in/ft - $.055

• 14BSM1.4 – 1500 inch feet Average street price $55 Cost per in/ft - $.043

• 14BSM2.4 – 3000 inch feet Average street price $60 Cost per in/ft - $.026

• 14BSM3.4 – 6000 inch feet Average street price $110 Cost per in/ft - $.023

As you can notice that your cost per foot decreases much more than the percentage of increased cost. If you cut frequently, a higher quality and stable performance diamond blade will save you much on your cost per cut and will usually cut faster all the time.

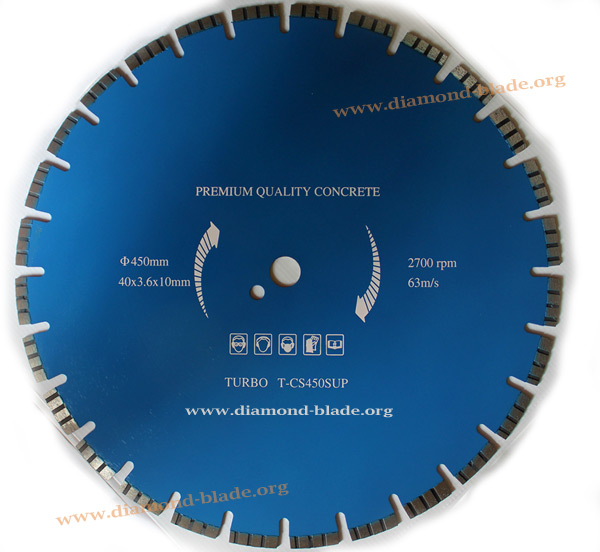

Safety - Even a low price may look like a bargain, however it always is not in the long work. Rule of thumb here is staying far away from those unmarked diamond saw blades. If the manufacturers are not willing to label their names on it, you should not trust them. Looking for branded diamond blades from reputable suppliers. It won’t certainly make the prices higher, but it will assure you a consistent quality diamond blade that the manufacturer will stand behind. Many online diamond tool sellers that declaim themselves as “manufacturer direct” don’t have any direct contact with any diamond tool manufacturer. Make sure your diamond saw blade supplier is ensured in case of any unexpected problems. Diamond saw blades without marks and label make it hard to track the suppliers.

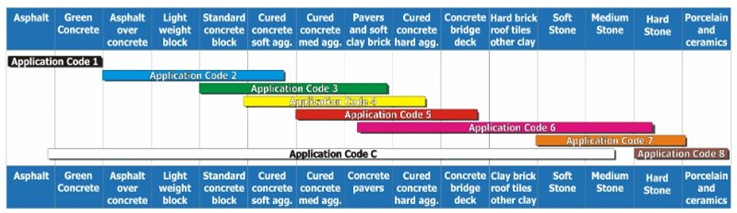

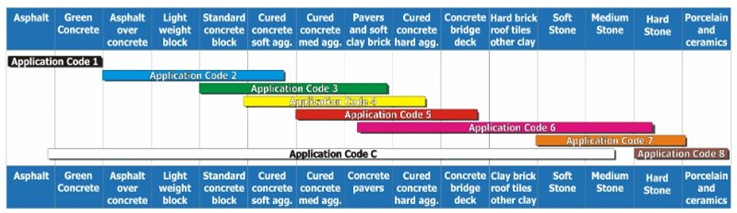

Applications – The term “general purpose cutting saw blade” is thrown around the world quickly and this should not be obscured with “combination cutting saw blade” or “multi-application cutting saw blade”. A general purpose saw blade always means the diamond and metal bond is made for cutting granite, marble, stone, concrete, asphalt, masonry block, brick or pavers. Do not rely on this saw blade for cutting those materials at the soft or typically hard end of the spectra. You generally won’t find a low cost diamond blade to cut all kinds of materials. The cost to manufacture a specific application diamond saw blade is much higher than manufacturing a general purpose one. If you want to cut as many materials as possible without having to change the diamond saw blade, you need a true combination diamond saw blade like our series code “C”. If you cut abrasive materials like asphalt or green concrete with a general purpose diamond blade, it will wear out the diamond blade as much as 75% faster than it is cutting the materials which was suitable for. If you try to cut typically hard materials with a general purpose diamond saw blade, it will become smooth and stop cutting. If you cut materials on either end of the hardness scale, you have to find special and suitable saw blade to that application for best results.

Commonly asked questions:

1. What does the term inch foot mean? Inch foot means one lineal foot at 1” depth. If you cut 10 feet at 4” depth, you would have a total of 40 inches feet.

So what exactly makes a diamond saw blade good ? In reality, it’s the most proper combination of cost, quality, speed and life that fits your demand. Take time to judge what diamond blade works best for you. A little research will help you to save time and money.

2. We cut large amounts of both asphalt and concrete. Is it make sense to use a combination diamond saw blade? In reality, you can get faster cutting and longer life by changing diamond saw blade blades for different application. We often hear that it is impossible to ask the operators to stop and change diamond saw blades when cutting different materials. If this is your plan, a combination diamond saw blade will reduce your costs down totally and reduce the chance of damaging a diamond cutting blade due to different application.

3. Does the height of the segment affect anything when it is about the life of the diamond saw blade? The answer is both yes and no. A lot of low costs diamond saw blades provide tall segments to make them look like having long life. Generally, you will see a bronze appearance to the diamond segment. It means that they have produced a soft bond to surround the diamond so that it will wear quickly. It is necessary because the diamond grits are low quality and will not last long life during cutting. If you compare a high quality diamond blade with 10mm tall diamond segments, and they have exact same quality with 15mm tall diamond segments, the size does matter. Don’t get caught in the game of size, be smart.

4. My operators don’t know how to cut granite and other similar materials properly, why is necessary for me to give them good quality diamond saw blades when they will probably just damage it? It is a question which we hear about a lot. A better quality diamond saw blade will always have heavier and thicker steel core than normal and have superior tension. The fact is that a “throw away” diamond saw blade will fail much easier than a better quality diamond saw blade when it is cutting stone and concrete. If your guys are damaging the diamond saw blades, just give them something that can handle the abuse better. From a point view of safety, cheap diamond saw blades in the wrong hands can be very dangerous.

Related Articles:

a. What is laser welded diamond blade?How the laswer welded diamond blade works?

b. How to safely operate a concrete saw?

c. What is laser welded diamond blade, how to distinguish it with other blades?

d. Concrete Saw Blades – Diamond Blades

No doubt, the diamond tools supplier has changed greatly from then on. The bond formula used today is much more tolerate, and the costs for cutting have dropped as much as 80% over the past 15 years. The lower cost has urged the market to a much greater team of diamond saw blade users and correspondingly volume has increased greatly. If you’re a new operate of diamond saw blades (diamond cutting blade), please think yourself have good luck that you didn’t to through the growing pains of the diamond tools industry. The charges are as lower as you will find totally, but there is still a very wide scope of price and quality grades available for you to select from. The most big problem you will encounter now is how to determine what diamond blade makes sense for you to use. However, there is no written standard on leveling diamond saw blades for cutting stone. You will find diamond saw blades labeled as “premium quality” that are actually not. In fact, most of the marketers call their whole production line premium, regardless of real quality and truth. We offer true diamond saw blade grading, based on its performance when cutting granite, marble and concrete. We offer precise 6 levels of quality based on the product type. Our company rule is that for every 15% more you spend on the diamond blade, you would see a minimum of a 25% increase in cutting performance and the output. Happily most of our diamond blades exceed that rating.

So at present you have knew that many of the quality ratings listed are meaningless, what should you pay attention to in a diamond saw blade? What’s correct for a user probably won’t be the same for others, so let us break this down by detailed requirements. We’ll take 14” concrete saw blade as the model since that is the biggest volume product which are sold around the world.

Price – Many users always look at the original cost of a diamond saw blade as the elemental factor when doing purchase. If you are planning to make a small amount of cuts and won’t have any further need for the diamond saw blade, it is the correct choice. You want the possible lowest costs connected with the job. What you don’t want is something too cheap to bring danger. In reality, a heavy user shouldn’t select price as his want. A higher priced diamond saw blade for concrete or stone will always yield much lower cost per foot than an economic diamond saw blade. For Example:

Cutting 3000psi cured concrete with medium aggregate and #3 steel bar, these are estimated inch feet for ChinShine brand concrete saw blades by quality (+/- 30% depending on operator and saw):

• 14BSM0.4 – 1000 inch feet Average street price $40 Cost per in/ft - $.055

• 14BSM1.4 – 1500 inch feet Average street price $55 Cost per in/ft - $.043

• 14BSM2.4 – 3000 inch feet Average street price $60 Cost per in/ft - $.026

• 14BSM3.4 – 6000 inch feet Average street price $110 Cost per in/ft - $.023

As you can notice that your cost per foot decreases much more than the percentage of increased cost. If you cut frequently, a higher quality and stable performance diamond blade will save you much on your cost per cut and will usually cut faster all the time.

Safety - Even a low price may look like a bargain, however it always is not in the long work. Rule of thumb here is staying far away from those unmarked diamond saw blades. If the manufacturers are not willing to label their names on it, you should not trust them. Looking for branded diamond blades from reputable suppliers. It won’t certainly make the prices higher, but it will assure you a consistent quality diamond blade that the manufacturer will stand behind. Many online diamond tool sellers that declaim themselves as “manufacturer direct” don’t have any direct contact with any diamond tool manufacturer. Make sure your diamond saw blade supplier is ensured in case of any unexpected problems. Diamond saw blades without marks and label make it hard to track the suppliers.

Applications – The term “general purpose cutting saw blade” is thrown around the world quickly and this should not be obscured with “combination cutting saw blade” or “multi-application cutting saw blade”. A general purpose saw blade always means the diamond and metal bond is made for cutting granite, marble, stone, concrete, asphalt, masonry block, brick or pavers. Do not rely on this saw blade for cutting those materials at the soft or typically hard end of the spectra. You generally won’t find a low cost diamond blade to cut all kinds of materials. The cost to manufacture a specific application diamond saw blade is much higher than manufacturing a general purpose one. If you want to cut as many materials as possible without having to change the diamond saw blade, you need a true combination diamond saw blade like our series code “C”. If you cut abrasive materials like asphalt or green concrete with a general purpose diamond blade, it will wear out the diamond blade as much as 75% faster than it is cutting the materials which was suitable for. If you try to cut typically hard materials with a general purpose diamond saw blade, it will become smooth and stop cutting. If you cut materials on either end of the hardness scale, you have to find special and suitable saw blade to that application for best results.

Commonly asked questions:

1. What does the term inch foot mean? Inch foot means one lineal foot at 1” depth. If you cut 10 feet at 4” depth, you would have a total of 40 inches feet.

So what exactly makes a diamond saw blade good ? In reality, it’s the most proper combination of cost, quality, speed and life that fits your demand. Take time to judge what diamond blade works best for you. A little research will help you to save time and money.

2. We cut large amounts of both asphalt and concrete. Is it make sense to use a combination diamond saw blade? In reality, you can get faster cutting and longer life by changing diamond saw blade blades for different application. We often hear that it is impossible to ask the operators to stop and change diamond saw blades when cutting different materials. If this is your plan, a combination diamond saw blade will reduce your costs down totally and reduce the chance of damaging a diamond cutting blade due to different application.

3. Does the height of the segment affect anything when it is about the life of the diamond saw blade? The answer is both yes and no. A lot of low costs diamond saw blades provide tall segments to make them look like having long life. Generally, you will see a bronze appearance to the diamond segment. It means that they have produced a soft bond to surround the diamond so that it will wear quickly. It is necessary because the diamond grits are low quality and will not last long life during cutting. If you compare a high quality diamond blade with 10mm tall diamond segments, and they have exact same quality with 15mm tall diamond segments, the size does matter. Don’t get caught in the game of size, be smart.

4. My operators don’t know how to cut granite and other similar materials properly, why is necessary for me to give them good quality diamond saw blades when they will probably just damage it? It is a question which we hear about a lot. A better quality diamond saw blade will always have heavier and thicker steel core than normal and have superior tension. The fact is that a “throw away” diamond saw blade will fail much easier than a better quality diamond saw blade when it is cutting stone and concrete. If your guys are damaging the diamond saw blades, just give them something that can handle the abuse better. From a point view of safety, cheap diamond saw blades in the wrong hands can be very dangerous.

Related Articles:

a. What is laser welded diamond blade?How the laswer welded diamond blade works?

b. How to safely operate a concrete saw?

c. What is laser welded diamond blade, how to distinguish it with other blades?

d. Concrete Saw Blades – Diamond Blades

Previous:How are diamond saw blades and diamond segment made? Next:Why select a diamond saw blade for granite is important?

Thank you for your interest in the above content, please leave us inquiry, you can expect a response within 24 hours.

Required fields are marked *

|

|

|

|