When concrete is scarred, pitted or damaged from installation, it may be necessary to grind the concrete rather than remove it and reinstall. Concrete grinding allows you to smooth and polish your concrete to form a smooth or shiny finish. If you are planning on grinding your concrete, then you should know about the tools, materials and techniques available for a successful project completion.

Rent a concrete grinder from your local tool rental store. A concrete grinder resembles a floor polisher. It has a handle with on and off controls, a 4-foot extension bar, and a round base that rotates in a circular motion. The stones are approximately 2 inches wide, 1 inch thick and 4 inches long. Ask your local tool rental clerk for operation instructions and directions on how to load the grinding stones into the base of the grinding machine. For countertops, use a sander and regular sandpaper.

Concrete polishing is a concrete finishing process that results in a smooth shiny concrete surface. A polished slab removes any lines left over from the concrete pouring process. DIY concrete polishing is achievable as long as you have the proper tools and follow the correct procedure. It’s mostly a matter of grinding out the imperfections on the concrete surface. Multiple passes with a grinder are necessary, and it’s a messy process, but once completed you’ll have a polished mirror-like reflective surface that not only adds beauty to the typical slab, but lowers maintenance requirements as well.

Concrete saws are available in several types and sizes. The hand-held concrete saw is the most common and least expensive version. These saws are usually operated with a gas and oil mixture. In some cases, professional companies use heavy duty concrete saws that are operated with hydraulics. There are many types of concrete saw blades, including metal and abrasive blades. The saws will occasionally feature a connection for a garden hose to cool down the blade while the saw is being operated. Most concrete saw suppliers offer discounts to contractors and construction companies that purchase saws in large numbers. Most of the retailers and wholesale companies that sell concrete saws also offer replacement blades for their product lines.

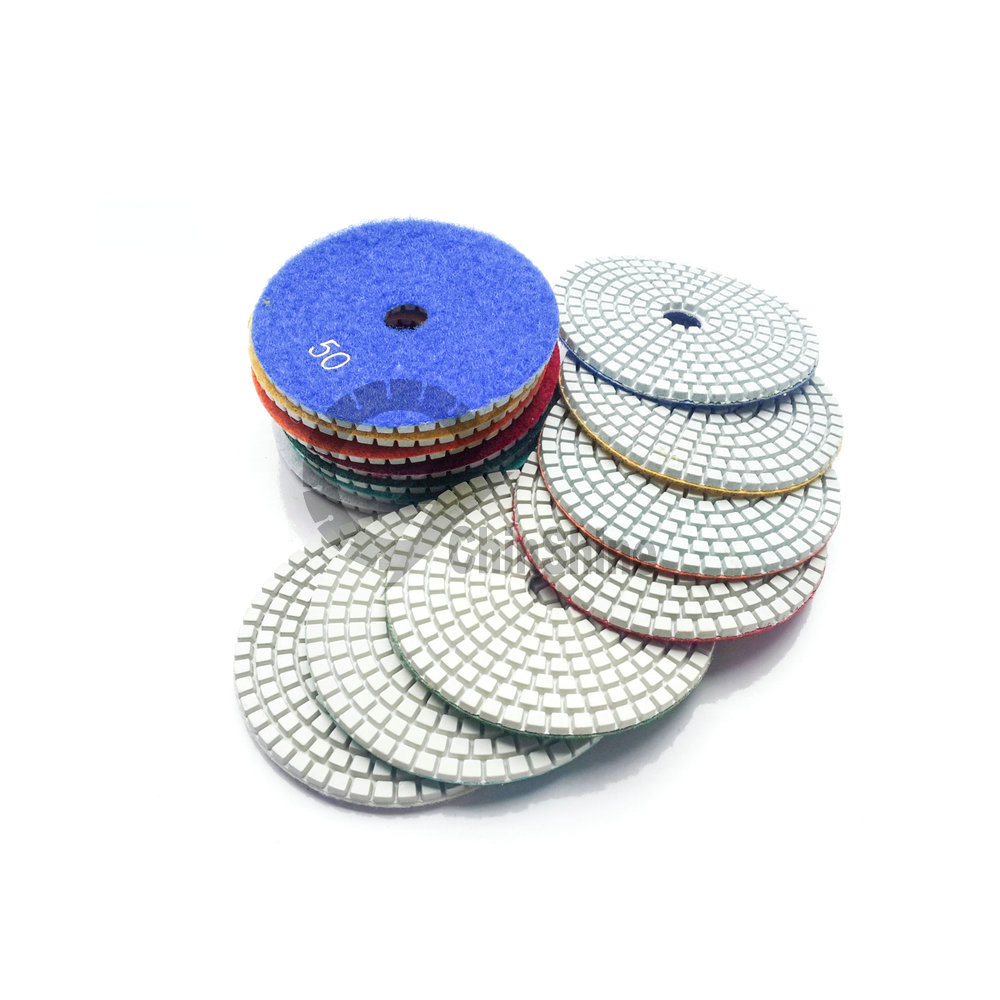

Concrete cutting tool- Diamond blades

These concrete cutting tools are being regarded as the best tool cutting equipments including clay pavers, brick, or various other forms of concretes found in the world market. These blades are also very vital in cutting different objects as per required and also help on giving exclusive designs. Of these concrete cutting tools, the diamond blades are being regarded as the most efficient and cost cutting blades too. These blades can also help in providing the various curbs for any concrete buildings, and is fastly growing popularity due to its versatile usage and sharp teeth.

Mainly all the concrete cutting tools have sturdy blades, these diamond blades can easily cut into the toughest and the ticker substances when rolled upon. Those personals who are working in the concrete field day in and day out know very well about the usage of these concrete cutting tools and also the versatility of diamond blade and also for choosing the right blades being used to provide traditional and modern designer look.

There are different factors which would determine the usage of these diamond blades. Some of these are being illustrated below like:

A diamond blade used in cutting concrete must be small or big in size, with high or medium toughness and its concentration power should be slightly below 25% to 30% or a little higher than this. A right combination of these diamond blades would enhance its efficiency and also helps in prolonging blades longevity;

As a concrete cutter you must choose diamond blade which has higher toughness, larger in size along with higher concentrated diamonds should be selected for these diamond blades;

The diameter of these diamond blades vary from big to small diameter blades. If you are choosing a big diameter diamond blade for concrete cutting the overall diameter size of the blade should be 36#-60# grit along with higher toughness. On the other hand, of you choose a medium or smaller sized diamond blade the blade should be 46#-70# grit. These combinations would be guarantee the right cutting effectiveness and also enhance the cutting excellence;

When choosing a diamond blades make your choice as per the stones dimension. These are necessary because the stone needs to be sawed and to be put back to the right processing quality wise;

The diameter of the diamond blade should be more than or equal to 300mm. The diameter of these diamond blades should vary upon the size they are being used upon. A thin and narrow diamond blade should be used if you require a nice soothing surface concrete finishing touch. Whereas, when used upon thick stone surfaces, wide-gullets diamond blades should be put into usage;

When you are using these diamond blades in cutting précised machines parts, diamond blades with high-quality abradability suppressions should be used into effect;

Diamond blade with soft bristles should be used in cutting fresh and précised cutting machineries;

If you are intending in cutting lower line speeds machines, those diamond blades which according to you has good- abradability bondage must be used.

Thus when it comes in cutting of concrete items, the best concrete cutting tools in the form of diamond blade or blades must be used. Those concrete contractors using these blades would get guaranteed success in their jobs whenever they put these diamond blades into good effect.

Rent a concrete grinder from your local tool rental store. A concrete grinder resembles a floor polisher. It has a handle with on and off controls, a 4-foot extension bar, and a round base that rotates in a circular motion. The stones are approximately 2 inches wide, 1 inch thick and 4 inches long. Ask your local tool rental clerk for operation instructions and directions on how to load the grinding stones into the base of the grinding machine. For countertops, use a sander and regular sandpaper.

Concrete polishing is a concrete finishing process that results in a smooth shiny concrete surface. A polished slab removes any lines left over from the concrete pouring process. DIY concrete polishing is achievable as long as you have the proper tools and follow the correct procedure. It’s mostly a matter of grinding out the imperfections on the concrete surface. Multiple passes with a grinder are necessary, and it’s a messy process, but once completed you’ll have a polished mirror-like reflective surface that not only adds beauty to the typical slab, but lowers maintenance requirements as well.

Concrete saws are available in several types and sizes. The hand-held concrete saw is the most common and least expensive version. These saws are usually operated with a gas and oil mixture. In some cases, professional companies use heavy duty concrete saws that are operated with hydraulics. There are many types of concrete saw blades, including metal and abrasive blades. The saws will occasionally feature a connection for a garden hose to cool down the blade while the saw is being operated. Most concrete saw suppliers offer discounts to contractors and construction companies that purchase saws in large numbers. Most of the retailers and wholesale companies that sell concrete saws also offer replacement blades for their product lines.

Concrete cutting tool- Diamond blades

These concrete cutting tools are being regarded as the best tool cutting equipments including clay pavers, brick, or various other forms of concretes found in the world market. These blades are also very vital in cutting different objects as per required and also help on giving exclusive designs. Of these concrete cutting tools, the diamond blades are being regarded as the most efficient and cost cutting blades too. These blades can also help in providing the various curbs for any concrete buildings, and is fastly growing popularity due to its versatile usage and sharp teeth.

Mainly all the concrete cutting tools have sturdy blades, these diamond blades can easily cut into the toughest and the ticker substances when rolled upon. Those personals who are working in the concrete field day in and day out know very well about the usage of these concrete cutting tools and also the versatility of diamond blade and also for choosing the right blades being used to provide traditional and modern designer look.

There are different factors which would determine the usage of these diamond blades. Some of these are being illustrated below like:

A diamond blade used in cutting concrete must be small or big in size, with high or medium toughness and its concentration power should be slightly below 25% to 30% or a little higher than this. A right combination of these diamond blades would enhance its efficiency and also helps in prolonging blades longevity;

As a concrete cutter you must choose diamond blade which has higher toughness, larger in size along with higher concentrated diamonds should be selected for these diamond blades;

The diameter of these diamond blades vary from big to small diameter blades. If you are choosing a big diameter diamond blade for concrete cutting the overall diameter size of the blade should be 36#-60# grit along with higher toughness. On the other hand, of you choose a medium or smaller sized diamond blade the blade should be 46#-70# grit. These combinations would be guarantee the right cutting effectiveness and also enhance the cutting excellence;

When choosing a diamond blades make your choice as per the stones dimension. These are necessary because the stone needs to be sawed and to be put back to the right processing quality wise;

The diameter of the diamond blade should be more than or equal to 300mm. The diameter of these diamond blades should vary upon the size they are being used upon. A thin and narrow diamond blade should be used if you require a nice soothing surface concrete finishing touch. Whereas, when used upon thick stone surfaces, wide-gullets diamond blades should be put into usage;

When you are using these diamond blades in cutting précised machines parts, diamond blades with high-quality abradability suppressions should be used into effect;

Diamond blade with soft bristles should be used in cutting fresh and précised cutting machineries;

If you are intending in cutting lower line speeds machines, those diamond blades which according to you has good- abradability bondage must be used.

Thus when it comes in cutting of concrete items, the best concrete cutting tools in the form of diamond blade or blades must be used. Those concrete contractors using these blades would get guaranteed success in their jobs whenever they put these diamond blades into good effect.

Previous:The Best Way to Cut Bricks Next:Buying the right diamond saw blade

Thank you for your interest in the above content, please leave us inquiry, you can expect a response within 24 hours.

Required fields are marked *

|

|

|

|