Angle Grinders use diamond cup wheels and diamond polishing pads to grind and polish the stone floor, concrete floor, countertops and other similar surfaces. There are several typles of diamond grinding tools that are used for processing shape and smooth the surfaces.

Diamond Cup Wheels

For grinding large amounts of material must be removed quickly, you should use diamond cup wheels, such as turbo diamond cup wheels, single row diamond cup wheels and double row diamond cup wheels. Diamond cups are rigid, all metal bonded cup wheels that have thick, diamond segments welded into the outer edge of the disc’s plate.

Diamond cup wheels come in a variety of styles and sizes. The most useful are coarse discs that are 4” or 5” in diameter. Larger diameters spin faster (and therefore cut faster) and are more stable and less likely to dig into the concrete surface. Smaller diameter diamond grinding wheels are useful for smaller sections of floor or edges. A special edge grinding wheel is available that has a smoother face and wider diamond segments. Some diamond grinding discs are designed to be run dry or wet; it depends on the style and manufacture technique.

Diamond Polishing Pads

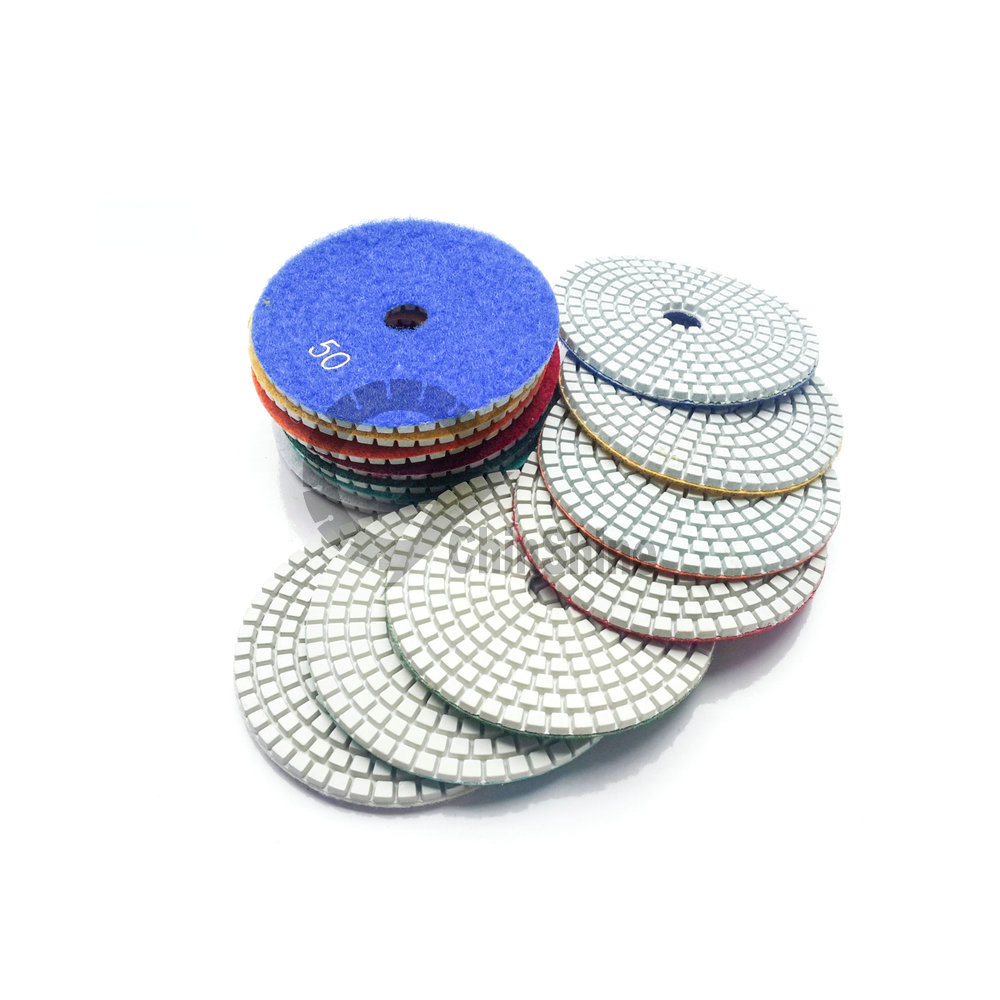

To smooth the floor (concrete surface, marble or granite floor, countertops, etc) after grinding with diamond cup wheel, or to polish/hone light grinding on a floor that does not have embedments in it, diamond polishing pads are the best choice. The polishing pads are thin, flexible, Velcro-backed, diamond-impregnated plastic discs that stick to a Velcro faced backer pad. The backer pad can be flexible or rigid, and can be either plastic or metal.

Diamond polishing pads come in a variety of grits, from 50 (coarse) to over 3000 (ultra fine). Most polishing pads at the coarser range (50 grit to 200 grit) are used for honing, while finer pads (400 to 3000 grit) are used for polishing.

Diamond Grit: #50, #100, #150, #200, #300, #400, #500, #800, #1000,#1500, #2000, #3000

Diamond polishing pads manufacturers desgin and make various shapes of pads for polishing different surfaces. You should inquire

It’s unnecessary to use the pads with grit more than 200 (or so), unless a polished, bare floor surface finish is desired. Usually only the #50 to #200 grits are used. A 200 grit pad produces a very smooth but matte surface. Most topical sealers will not stick to a surface honed finer than 200 grit. Even if a sealer will stick to the polished surface, it is often impossible to tell the difference between a sealed floor surface honed to 3000 grit and a sealed floor surface honed to only a 200 grit. Essentially, polishing floor is a waste of time if a topical sealer is used.

If you do want to a polished surface that you will apply only a penetrating sealer or densifer to, then continue the grit progression all the way to #3000.

Please note: don't skip grits. Each grit in the progression is designed to smooth out scratches from the previous grit. A 3000 grit pad is incapable of smoothing out scratches from a 200 grit pad, no matter how long you grind it.

Related Articles:

a. How to Polishing and Grinding Marble?

b. Grinding and Abrasive Tools improvement.

|

How to use diamond cup wheels and polishing pads for concrete floor |

Previous:Mortar Joints Removal Using a Diamond Blade Next:How Diamond Saw Blades work

Thank you for your interest in the above content, please leave us inquiry, you can expect a response within 24 hours.

Required fields are marked *

|

|

|

|